ABUS EOT and jib cranes at a pump manufacturer’s site in Sweden

Xylem (www.xylem.com) is a world-leading manufacturer of pumps and systems to safely pump and distribute water. Their Swedish site at Sundbyberg, north of Stockholm, recently saw an expansion of the Xylem Water Solution AB: They are now housing a service department which is going to work closely together with the international development department already on site. The aim is to better document the demands and requirements the products of the company are subjected to over their entire service life.

When the existing building was converted it was stipulated that the existing cranes and lifting solutions should be reused as far as possible—Xylem has made sustainability an overarching company objective. Other important components of the company culture are social engagement and social commitment. The company, for example, donated an optimised control system for the pumps used at the Swedish open air museum Skansen: These pumps achieved a considerable reduction of energy use and thus a reduction in energy costs. In the summer of 2018 Xylem provided the pumps and staff for the rescue of the young people trapped in an underground cave in Thailand. These pumps managed to reduce the water level in the cave system despite continued rain.

Extensive scope of supply

Xylem in Sundbyberg employs 400 staff in total. Sundbyberg houses the departments for national and international sales, development, and service. The first step in fitting out the new service department with crane and lifting equipment consisted in moving the existing ABUS EOT cranes and their crane tracks to the new site: “One factor that contributed to us being so successful in carrying out this complex project was the support we enjoyed from Simon Larsson, the construction engineer at JJ Gruppen, a subsidiary of the Swedish ABUS Kransystem AB (www.abus-kransystem.se), and a steel workshop in Linköping”, reported Magnus Lindén who is the responsible salesman for JJ-Gruppen in Stockholm and the surrounding area.

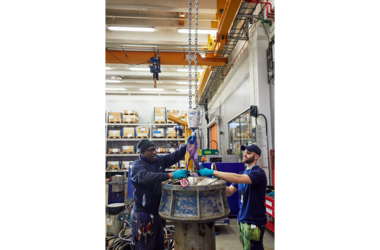

New jib cranes and EOT cranes were used in addition to the reused cranes. A pillar jib crane of the VS type with a height of over 8 metres, a load capacity of 4 tonnes and a jib arm length of 5 metres was supplied among others. This jib crane features an electric wire rope hoist and was mounted in the underground car park. It serves the loading area on the level above through an opening between the levels. All movements of the crane are electric due to the SWL of 4 tonnes, i.e. the crane features electric slewing as well as electric trolley travelling. The project also includes a 32 metre long crane track with three single girder underslung EOT cranes of the EDL type and each of them comes with two hoists with load capacities of 4 tonnes each. The underslung EOT cranes feature rolled section girders and screwed main girder connections. This type of crane is particularly suited to complicated space and construction conditions as the crane track is mounted onto the ceiling instead of onto pillars. In addition, lower trolley end approach dimensions allow the optimal use of the exiting bay width. The main girder slots in between the end carriages which means that the highest hook position can be optimised also. A separate crane track was fitted with a single girder EOT crane of the ELV type with two electric chain hoists with SWLs of 1 tonne each which give it a total load capacity of 2 tonnes in this case. The control of the crane, an ABUS radio remote control ABURemote Button, allows the hoists to be used individually as well as in tandem. The jib crane is also controlled by radio remote control so that the crane user will be able to move loads while standing in a safe place and keeping an eye on all crane movements.

Four workshop cranes complete the building’s crane park: Jib cranes of the LS type with safe working loads of 1 tonne each and jib arm lengths of 3 metres. These cranes are used to move smaller components directly onto the work benches of the work places in order to check them for possible damages. Slewing and trolley travelling are manual as the SWLs are quite inferior compared to the big VS jib crane. The electric chain hoists are operated via push button pendants on these cranes.

Thus the ABUS EOT cranes and jib cranes work together on two levels for an optimised material flow. The EOT cranes transport heavier loads across the entire bay while the smaller jib cranes are serving the work stations: they make it quick and efficient to load individual work benches.