Choosing the right crane optimises production processes and reduces hall construction costs

Ruland Engineering & Consulting Sp. z o.o. (www.rulandec.com) are an international company operating on the world market for equipment for the food industry for 27 years. Ruland are a mechanical engineering company specialising in liquids and offer modern solutions for the beverage, juice and brewery industries.

Ruland offer comprehensive services in Poland—from process engineering consulting to the design and manufacture of plants and their assembly to the commissioning of the entire plants at the customer’s factory as well as their maintenance—all is included. The company’s extensive portfolio includes projects for the biggest food brands on the European, Asian, African and South American markets.

Ruland aim to combine the demand for technological innovation with the highest quality of equipment supplied. They strive to support the customer in selecting optimal solutions at every stage of the projects.

Quality and shared values matter when selecting business partners

Ruland decided to expand production and storage capacities in Poland when implementing their development plan.

The investment gave Ruland Tychy 1,300 square metres of additional space increasing production capacity and improving working conditions for their employees. Ruland turned to their long-standing partner ABUS Crane Systems Polska, the Polish subsidiary of ABUS Kransysteme GmbH, to select the cranes when planning the new hall. ABUS was again chosen as the supplier for further overhead travelling cranes as chain and wire rope hoists used so far had proven to be reliable.

Selecting the right crane means optimising costs

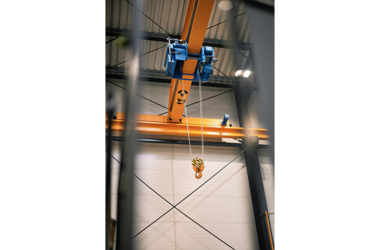

The ABUS sales engineers suggested the use of two ELK single-girder overhead travelling cranes with an SWL of 10 tonnes and a span of 25 metres since large components for tanks are to be manufactured in the new hall. The cranes are designed with the so-called main girder connection variant 3: The lower flange of the crane’s main girder is at the same height as the head of the runway which enables optimum utilisation of the hall height. Thus, the investment costs are reduced with this variant 3 arrangement. Optimal crane approach dimensions can also be realised in the new building thanks to this particular crane design.

The large free space under the crane is necessary due to the large height differences of the manufactured equipment. It also makes loading and unloading of lorries and containers directly in the production hall much easier. Lifting and turning large loads is a particular challenge for the crane operator. This is the reason why ABUS Crane Systems Polska recommended equipping the cranes with the ABURemote radio remote control system taking occupational safety into account among other things. The ABURemote enables the operator to have full control of the transported goods from a safe distance; this also effects the efficiency of the entire process positively. Work that previously had to be done with a truck-mounted crane is now carried out by EOT cranes. This has made it possible to significantly reduce the work steps involved in loading and unloading the equipment and occupational safety was improved.

The cranes are also equipped with a redundant photo-electronic crane spacing system that ensures a distance of 6 m between the two cranes is kept. The use of this system enabled significant savings to be made in the construction of the hall as the load transferred from the crane to the steel supporting structure is reduced which in turn enabled savings to be made on the steel and the size of the foundations. The use of ABUS cranes can thus both streamline the processes of internal transport and reduce the costs of the building construction.

At the time of writing, the investment process of RULAND Engineering & Consulting sp. z o.o. has been completed. The production parameters achieved in the new plant speak in favour of ABUS crane systems.