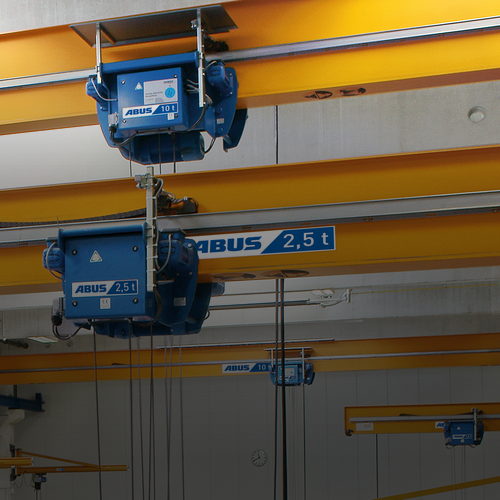

ABUS EOT cranes in Brazil working for a supplier of the automobile industry

Partnership based on trust

Many of ABUS’ customers in Germany have been regular customers over many years. Yet in the overseas export markets there are also customers who have relied on ABUS products and ABUS agents for a long time. The company Eidt-Ciriex (www.ciriexabus-cranes.com.br) for example started their sales activities in the Brazilian market twenty years ago to exclusively promote the ABUS brand. At that time Brazil only started to open up to imported goods which made it rather tricky to introduce new products and have the market accept them too. However, already in the initial phase Eidt-Ciriex managed to convince one company of the quality of the ABUS products: this company Bruning Tecnometal became one of their first—and until today one of their most prominent—customers in Brazil. Both companies are linked by a trusted business relationship and the sheer number of ABUS cranes in the Bruning plants testify to it.

From small service company to global supplier

The company Bruning Tecnometal (www.bruning.com.br) was founded at Panambi, a small town in the south of Brazil, in 1947 to service imported agricultural machinery. After some years Bruning started to construct smaller agricultural machines themselves. In 1967 Bruning began with the serial production of components for grain harvesters. Another milestone in the company’s history came in 1995: Bruning did not only produce individual parts and components for lorries but also started with the serial production of components for the automobile industry. Today well-known automobile companies such as Volvo, John Deere, Scania, and Benteler Automotive are counted among Bruning’s customers. And Bruning keeps growing: since 2012 a further sector is being developed, namely the construction machinery industries. Bruning produces serial components for these also. The company keeps expanding rapidly and at the end of July 2013 the “Fábrica II”, i.e. the plant no. II, was inaugurated. Bruning has also received various supplier awards.

Technical assistance and crane optimisation by Ciriex-ABUS

Bruning is using state-of-the-art technology in the new plant that has 15,200 square metres of production surface: from a welding robot to machining centres and even to a plasma cutter. The ABUS cranes, too, are subject to high requirements. According to Mr Elton Nunes, responsible for the construction of the new plant, 5,000 tonnes of loads are moved on average per month. More than 250 ABUS crane systems are used to transport raw materials such as steel plates, punching and stamping tools, packaging, components for the production processes, tools in the process of being built or being serviced, and welding templates to their respective destinations across a total production surface exceeding 110,000 square metres. All of ABUS products have a role to play: EOT cranes transport the more important loads, jib cranes are primarily used as work station cranes, and the suspended rail systems optimise the material flow of less heavy loads. Each crane system is the result of intense technical assistance by Eidt-Ciriex always aiming for best ratio of cost to benefit. Eidt-Ciriex mentioned one crane system needed for the transport of steel plates of a length of six metres. The customer specified an EOT crane with two suspension points. The solution offered by Eidt-Ciriex consisted in a double girder EOT crane with two wire rope hoists (with load capacities of 6.3 tonnes each). The operation of the hoists is synchronised by a synchronisation control system. The crane can thus be operated with both hoists simultaneously or just with one hoist depending on the application which makes for a very flexible crane system. The ABUS supply is rounded off by services such as maintenance.