ABUS EOT cranes and HB systems at the company EgoKiefer AG in Switzerland

Windows have always had the purpose to let light and air into buildings. However, today a window is not just a window: Windows are building elements and have to meet the highest demands of design, safety, and technology. Thermal insulation reduces the loss of heat, and sound proofing keeps the noise out. Using laminated safety glass provides additional safety should the glass shatter and also protects against burglaries. Architects use windows as design elements. They give new buildings individuality through their selection of window sizes and frame materials. However, listed buildings require that windows, and window frames in particular, should complement the external façade perfectly thus conserving the original character of historic buildings.

The company EgoKiefer AG (www.egokiefer.ch), one of the leading Swiss producers of windows and doors with headquarters in the town of Altstätten in the canton of St. Gall, has a total of 13 sales points all over Switzerland. EgoKiefer’s product range satisfies the varied and manifold customer requirements. The company EgoKiefer AG dates back to 1932 when Mr Ernst Göhner first acquired a joinery thus laying the cornerstone for the company. Today EgoKiefer AG see themselves as integrated suppliers of window solutions using materials and combinations such as vinyl, vinyl / aluminium, timber, and timber / aluminium. EgoKiefer also supply doors for external applications. The company has about 1,000 staff that produced over 663,000 m² of windows in 2013, all designed according to the individual requirements of their customers, as well as 2,840 exterior door units. A service team of 80 staff is available for assistance with any matters concerning doors and windows. Economic production methods, high-tech production lines, their own research and development departments, and a holistic system for quality, for safety, and for environmental friendliness make for first-class products and services.

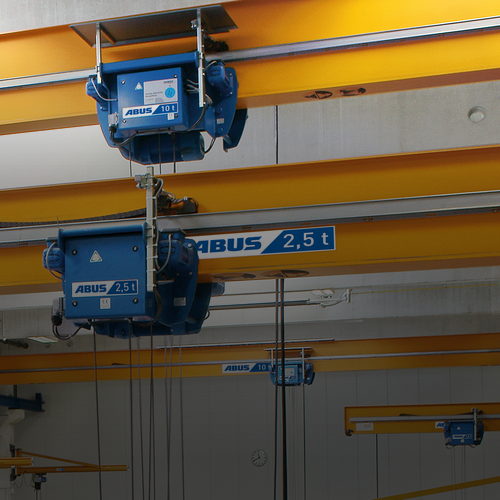

The high quality standards of EgoKiefer AG are also applied to the production processes which are continually optimised. When it comes to the conception of the systems for the internal transport and the material transport EgoKiefer have relied on the company Marti-Dytan AG (www.brunmartidytan.ch) with headquarters at Horw-Luzern for many years. Marti-Dytan is the Swiss distributor for ABUS crane systems. Once specialised engineers of Marti-Dytan had analysed in detail the requirements of EgoKiefer they advised them to install four ABUS single girder cranes type EHB with load capacities of 500 kg each from the ABUS product range of suspended rail systems. This modular HB system is capable to fit almost all shapes and sizes of rooms and halls and is able to lift up to 2 tonnes of loads when fitted with ABUS electric chain hoists. EgoKiefer AG continuously operate these HB systems in connection with suction lifters to handle the windows in their production plant. For logistic purposes they use ABUS single girder cranes type ELK with load capacities of 2.5 tonnes to load and unload lorries. The load hooks of the EOT cranes have been fitted with automatic catch and opening systems. The cranes are also frequency controlled that allow sensitive loads to be offloaded and positioned precisely when using reduced speeds. The EOT cranes are operated via radio remote control to enable the crane user to keep an eye on the whole area of the loading zone from a safe distance. Mr Hans Beutler, head of technical services at EgoKiefer AG, stressed that adding safety to the system was very important to the company, but they were also pleased with the improved design layout of the material handling system which had been achieved perfectly with the ABUS crane systems.